How Thermal Imaging Process Improvements Can Save You Time and Money

FLIR Routing allows a single trained thermographer to support a dozen or more data collectors.

No modern company can afford to maintain traditional or ‘old’ ways of working if they want to compete with today’s agile competitors. New and improved processes can aid the bottom line and selecting the right suppliers, equipment and partners will contribute significantly towards improving your own. If your business relies on thermal imaging in your Condition Monitoring Process, then Teledyne FLIR’s latest software developments might provide the process improvements your company needs.

Thermal imaging is typically a specialized and time-consuming process which needs to be repeated regularly to identify developing faults before they become too serious. However, the development team at FLIR has focussed on improving the thermography inspection process to find improvements beyond the thermal camera specs themselves.

FLIR has developed FLIR IGNITE, a cloud-based image back-up service that eliminates the need for transferring files to your reporting software through a cable or SD card reader. FLIR thermal cameras can be connected to local WIFI networks to synchronise their files into the IGNITE cloud, which can be linked to FLIR Thermal Studio reporting software to seamlessly transfer files from the thermal camera, through the IGNITE cloud, and directly to the Thermal Studio reporting software automatically.

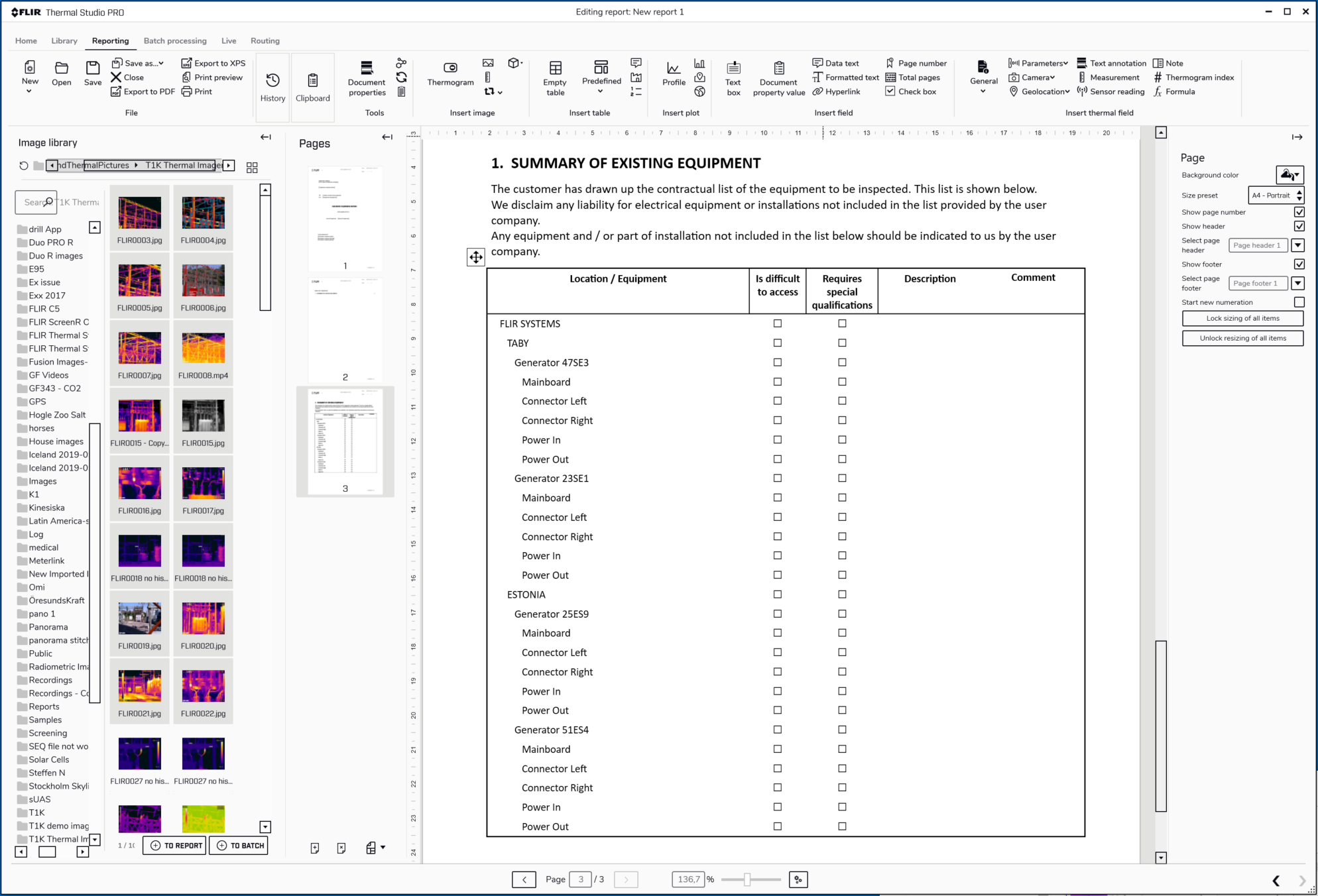

Reporting is another potentially time-consuming aspect of thermography that Teledyne FLIR has worked hard to improve, especially for repeat inspections of the same equipment. Thermographers can save hours on every repeat inspection using FLIR Thermal Studio and its Route Creator plug-in which allow a trained and experienced thermographer to set-up an inspection route for future thermal inspections. Once the initial inspection route has been created, previous thermal images and their data will automatically populate into a pre-defined report in the correct order on every repeat inspection, allowing easier thermogram comparison and analysis.

Summary of existing equipment for an inspection, created with FLIR Route Creator Plugin and viewed through FLIR Thermal Studio.

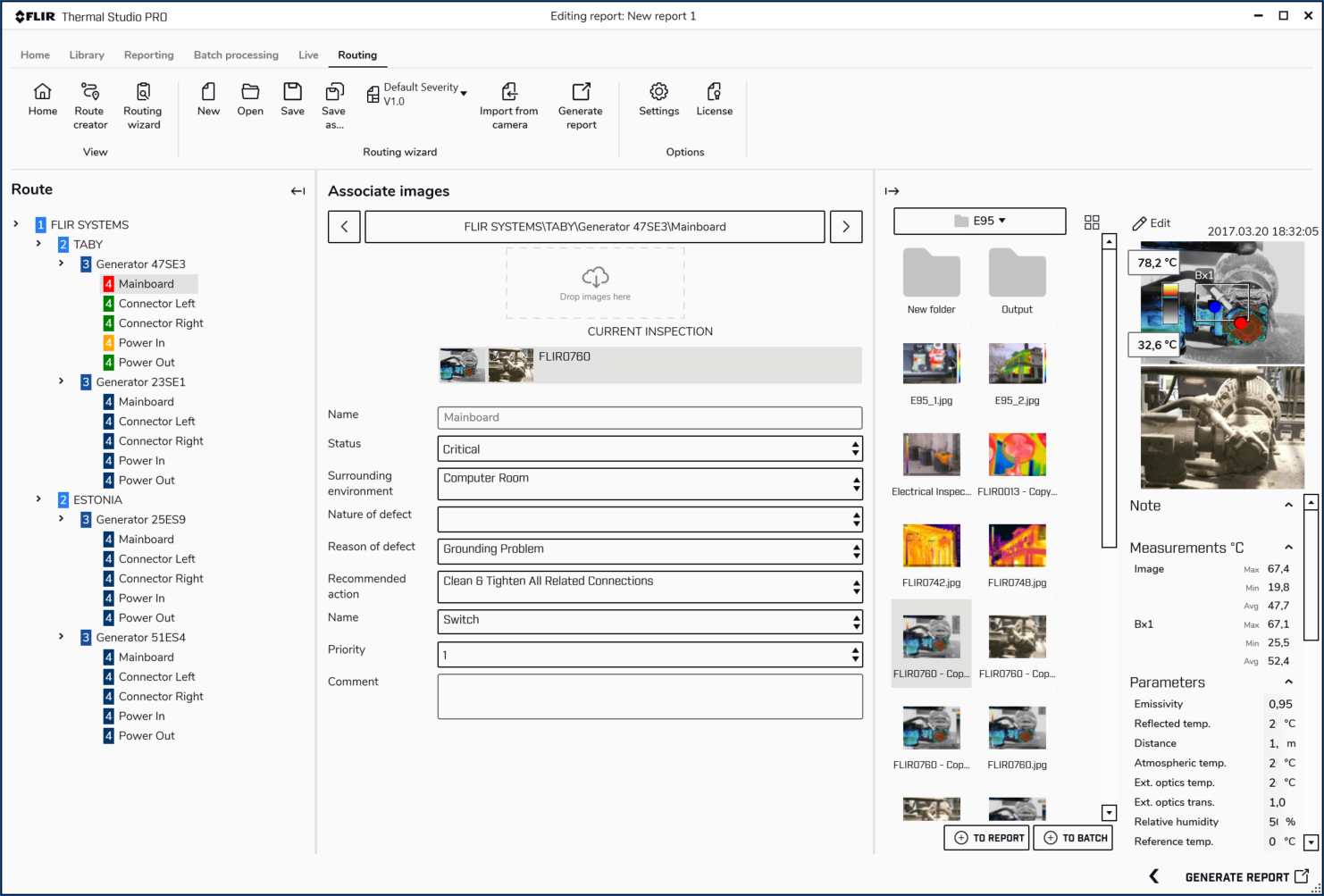

Teledyne FLIR has additionally developed its Route Creator plug-in to memorize the previous inspection level and span settings for each asset being inspected. This means the first inspection can be undertaken by an experienced thermographer to ensure the correct settings are used, and then repeat inspections afterwards may be conducted by less experienced thermographers who can rely on the memorised settings to capture an accurate image.

FLIR Route Creator allows you to see the previous settings used underneath the images on the right side.

Further enabling less experienced thermographers to conduct repeat inspections, FLIR Route Creator now displays the previous image taken on each asset in order, in the corner of the camera screen. This means that every time a repeat inspection is undertaken, the camera operator can see the image of each piece of equipment taken during the last inspection, allowing them to align the image they are currently taking for easier comparison and analysis.

The culmination of these continuous developments and updates is that businesses can save time when using thermal imaging to inspect their equipment. Extracting the same work in less time can potentially create considerable savings for business that regular perform thermal inspections.

If companies find it difficult to train their engineers who are responsible for condition monitoring to higher levels of thermographic competency, then they can also consider an approach such as using external consultants to set-up inspection routes and help analyse their data annually, with lesser experienced thermographers conducting regular thermal inspections throughout the year.

One of Teledyne FLIR’s development priorities is to continuously improve the processes of using thermal imaging to protect company equipment and simplify operation. Today, the capability of FLIR thermal cameras, FLIR Ignite cloud-based image backup, FLIR Thermal Studio reporting software and FLIR Route Creator Process Efficiency plug-in are responsible for a multitude of thermal inspection improvements already. Future FLIR developments will ensure that companies who use FLIR products and services will benefit from customer-centric updates that improve their processes, protect their equipment, and help maintain their competitive edge through condition-based monitoring activities.

Visit https://www.flir.eu/instruments/condition-monitoring-solutions/ to learn more about the Condition Monitoring solutions available, and contact one of our experts via this webpage to organise a meeting or to book a demo with a FLIR Product Specialist.