Ensure Operational Efficiency and Maintain Energy Flow

![]()

FLIR Total Solution for the Hydropower Industry

Hydropower is an important form of renewable energy, making up more than half of the renewable energy used globally and more than 16% of power generation from all sources. It's critically important, therefore, to maintain operations from hydropower stations, through midstream utility connections, and downstream to the electrical power grid that keeps homes, businesses, and cities running.

Regular predictive maintenance inspections—as well as continuous monitoring and enhanced perimeter security—can ensure the continued flow of electrical power. This is possible with handheld thermal, acoustic, and optical gas imaging cameras as well as fixed thermal-enhanced cameras.

Hydropower Applications

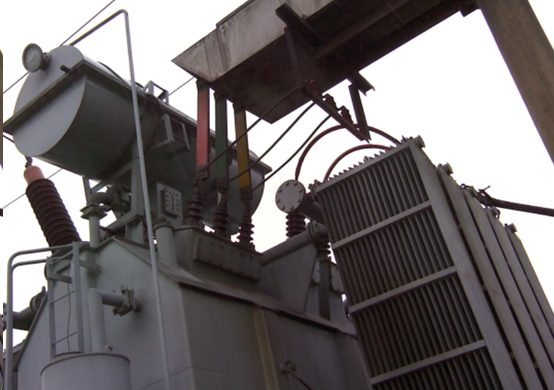

Electrical Systems Inspection

Inspectors can use thermal and acoustic imagers to check lines for partial discharge and loose connections, inspect electrical components, and survey switchgear for signs of overheating or faulty components.

Regular Maintenance

Regular thermal, acoustic, and optical gas inspections involve monitoring components temperature irregularities, partial discharge, and sulfur hexafluoride gas leaks. Combined with FLIR analytics software, these inspections provide valuable data for predictive maintenance, allowing operators to schedule repairs before problems escalate.

Equipment Inspection

Thermal imagers can be used to inspect turbines, generators, cooling systems, transformers, and other critical equipment for abnormal temperature patterns. Hot spots can indicate potential problems such as electrical faults, worn bearings, blockages, pump issues, inefficient cooling or lubrication issues.

Dam Integrity

Handheld and fixed thermal imaging cameras can be employed to monitor the temperature distribution on the dam surface. Temperature variations might indicate seepage or structural issues that require attention.

Pipeline Inspection

Thermal imagers can identify blockages, leaks, or temperature irregularities in pipelines carrying water to and from the plant. This aids in preventive maintenance and avoids disruptions.

Control Room Monitoring

Fixed thermal sensors—whether they offer on-the-edge analytics or simple integration into existing monitoring systems—can monitor control room equipment remotely, 24-7. Any anomalies that happen will trigger alerts, enabling timely actions to prevent failures.

Security

Dams, hydropower stations, and substations must be protected from intruders who could interfere with the flow of electricity. Thermal security cameras can detect and analyze potential intruders even in poorly lit areas or at night.

Leak Detection

The hydroelectric power grid can experience a range of leaks—from water leaking from pipes and hydraulic components, to compressed air leaks, to leaking SF6 insulaton from substation transformers. Detecting these leaks with thermal, acoustic, and optical gas imaging cameras helps reduced maintenance costs and ensures efficient operation.

The FLIR Total Solution

Teledyne FLIR technologies for the renewable energy industry are powerful, non-invasive tools for monitoring systems and diagnosing failures. They allow inspectors to identify problems early, document them, and schedule repairs before they break down and force costly replacements.

The FLIR Total Solution includes:

- Thermal, acoustic, and optical gas imaging cameras

- Inspection route guidance

- FLIR Ignite provides secure direct data storage, FLIR Thermal Studio software provides rapid reporting, and analyzing

- Training and service

FLIR Products for the Hydropower Applications

FLIR offers a range of handheld and fixed monitoring tools as well as inspection and analyzing software—all designed to monitor the system and components and ensure the operating efficiency of hydropower stations.

Handheld thermal cameras Fixed thermal cameras Test and Measurement tools

GAS LEAK DETECTION CAMERAS Software Acoustic Imaging Cameras

FLIR Si124-LD Plus

Industrial Acoustic Imaging Camera for Compressed Air Leak Detection

View Product Professional Reports that Help Your Customer and Your Business

Professional Reports that Help Your Customer and Your Business

The right image analysis and reporting software can greatly improve your business by making it easier for you and your customers to understand the problem and feel confident that you fixed it.

The advanced analysis and decision-making support offered in FLIR Thermal Studio Pro includes a rich set of measurement tools, batch processing, the ability to pre-plan inspection routes, and customized report templates.

Infrared Thermography Training Resources

Infrared Thermography Training Resources

Sign up for scheduled infrared thermography training courses offered through the Infrared Training Center (ITC).

Learn more

Do you have a large group that requires thermography training? The ITC will organize an onsite training course.

Request training