Inspectahire relies on the FLIR GF320 Optical Gas Imaging camera for maintenance inspections and hydrocarbon leak detection in the offshore oil and gas industry

Established in 1981, Inspectahire is a leading international supplier of specialist remote visual inspection technology and solutions to companies in many industries around the world. Supported by the most advanced technologies around, Inspectahire helps its customers manage their safety, profitability and environmental impact of their assets. When the company is tasked with the detection of fugitive hydrocarbon emissions, FLIR’s GF320 Optical Gas Imaging (OGI) camera is their preferred technology to use.

Inspectahire offers equipment rental, contracting and project engineering services supported by a team of skilled engineers who have a wealth of inspection knowledge and experience. Their expertise extends to a wide range of equipment and assets, both onshore and offshore, and in all environments – including harsh and hazardous. All Inspectahire’s advanced inspection solutions are carried out in accordance with the requirements of ISO 9001 best practice.

Oil & gas industry

Having worked for three decades in the Oil & Gas industry, both in the North Sea and worldwide, Inspectahire has built up a strong expertise in this sector. Safety and cost are two of the biggest concerns in the offshore oil and gas industry today. Inspectahire realizes this as no other and therefore aims to tackle those challenges by using the best technologies available.

“The offshore oil and gas industry are proactive in their search for the best technologies for detecting emissions that may affect the safety, profitability and environmental impact of their assets,” comments Cailean Forrester, Managing Director of Inspectahire. “At Inspectahire we strive to identify and offer the best available technological solutions for all remote inspection scenarios.”

Safety & economy

Dangerous gas leaks are a concern to every oil and gas production plant. Not only do some of the gases harm the environment, but the leaks also cost companies substantial amounts of money. “The company has been using thermal imaging cameras for a very long time to detect dangerous gas leaks,” comments Cailean Forrester “Thanks to thermal imaging cameras, we can easily detect gases in difficult to reach or hazardous locations. And we can help companies prevent costly downtime of their production plant.”

Contact measurement technologies vs. thermal imaging

“We have been using certain contact measurement tools like laser detectors or leaks sniffers,” says Cailean Forrester. “But the problem is that you have to go right up to the object, which is not always safe or even possible. In other words, this approach is limited and not very precise. With a thermal imaging camera like the GF320 however, you can keep a safe distance and still detect gas leaks with great precision.”

Accurate and ergonomic

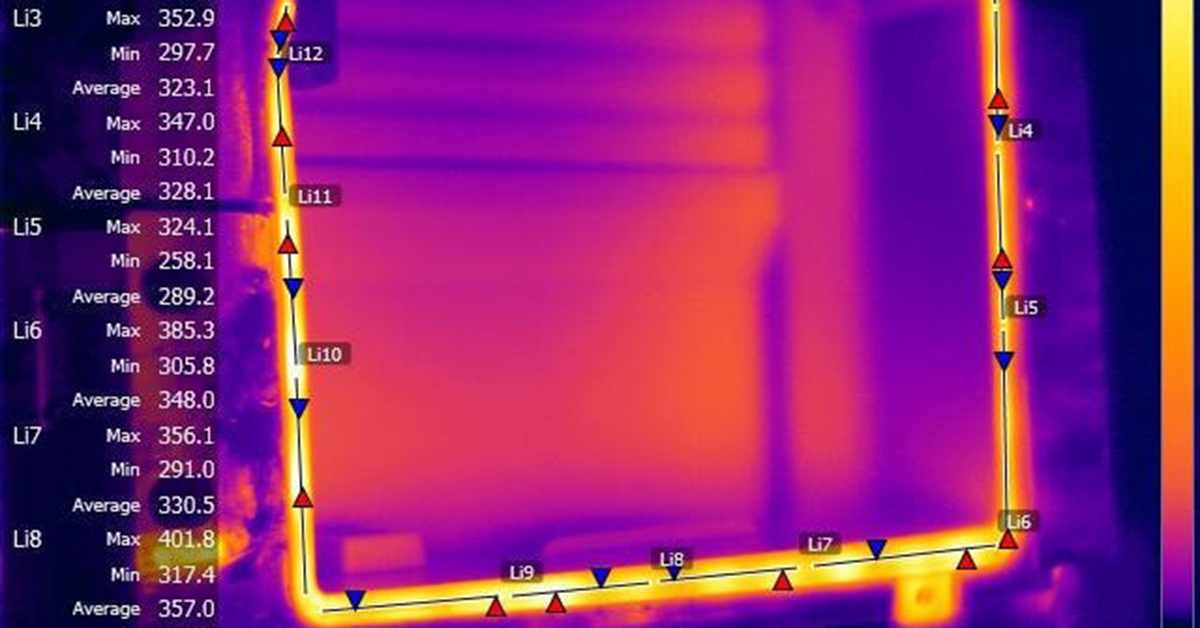

The Inspectahire team is using the GF320 optical gas imaging camera for maintenance inspections and for all its hydrocarbon detection jobs, in hydrocarbon production plants or for the inspection of any material that uses hydrocarbon as a fuel. The GF320 camera offers a range of tangible benefits compared to traditional hydrocarbon leak sniffers, because it can scan a broader area much more rapidly and monitor areas that are difficult to reach with contact measurement tools. The portable camera also greatly improves operator safety, by detecting emission at safe distance.

“The camera is very ergonomic and very sensitive,” comments Cailean Forrester. “If a hydrocarbon leak is there, you will certainly see it with the GF320 camera, even if it is a small one. Small leaks can become big ones, that is why it is important to be able to detect them in an early stage. With the GF320, we are sure of an accurate and reliable detection.”