Optical gas imaging for the chemical industry

Optical gas imaging cameras are a proven method to detect dangerous and costly gas leaks in time. Optical gas imaging technology has been successfully applied in the oil refining, chemical, petrochemical and many other industries to help improve worker safety and prevent costly production shutdowns.

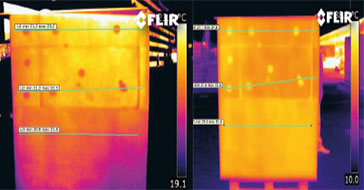

Chemical compounds and gases are invisible to the naked eye. Yet many companies work intensively with these substances before, during and after their production processes. The FLIR Gas Detection cameras are infrared cameras which are able to visualize gas by utilizing the physics of fugitive gas leaks. The camera produces a full picture of the scanned area and leaks appear as smoke on the camera’s viewfinder or LCD, allowing the user to see fugitive gas emissions.

The petrochemical industry produces hydrocarbon and other substances using base feed stocks from the oil refining companies either by conversion processes or further separation that is not normally carried out at an oil refinery. Most of the chemicals used or made in these industries have good visibility using the mid wave gas detection camera. The chemical industry produces non-hydrocarbon or inorganic chemicals from base feed stocks. These are often a mixture of batch and continuous processes that yield very high purity products. The mid wave gas detection camera has a good response to a lot of chemicals found in this sector.

Safety

The key success factors of optical gas imaging cameras for businesses are safety, efficiency and profitability. A gas detection camera is a quick, non-contact measuring instrument that can be used in hard-to-access locations. It can detect small leaks from several meters away and big leaks from hundreds of meters away. This way, operators do not need to approach the leak from close by, which improves the safety significantly.

Efficiency

Working with sniffers or probes can be very time-consuming and a lot of the time spent inspecting installations that are safe and leak-free is wasted. Using a Gas Detection camera you get a complete picture and can immediately exclude areas that do not need any action. This saves a lot of time and personnel. With a gas detection camera, measurements can be carried out remotely and rapidly and – most important of all – problems can be identified at an early stage.

Environmental regulations

Optical gas imaging allows the industry to comply with new industrial emissions regulations & procedures as set by the new IED (Industrial Emissions Directive) within the EU as part of the BREF (Best Available Technique Reference) for Refining or Mineral Oil & Gas. Chapter 5.1.4 is the draft BREF conclusion, for the Refining or Mineral Oil and Gas industry sector, stating optical gas imaging is one of three BAT (Best Available Techniques) which must be used for monitoring diffuse VOC emissions.

Optical Gas Imaging Cameras: buy or loan?

Although the cost of optical gas imaging cameras has decreased in recent years, purchasing a gas detection camera is still a significant investment for a lot of companies. According to Frank Zahorszki, CEO of Itema GmbH, a German service company specialized in thermographic inspections, the purchase price of an optical gas imaging camera should not deter smaller chemical companies from making use of this technology. “Today, more and more companies are contracting outside service providers for leak detection and repair to specialized service companies”, says Zahorszki. “This begs the question whether your company should buy or loan an optical gas imaging camera.”

The two main reasons for a plant buying an OGI camera are the amount of targets to inspect and the just-in-time availability of the camera in case of a leak. Companies that only require one to five inspection days per year, or companies that have the convenience to wait for a service company to come over, will opt for an external contractor. Very often, companies need to monitor different types of gases with different types of cameras, which justifies an external service provider even more.

The gas detection camera technique has a wide range of potential uses in the chemical and petro-chemical industries.

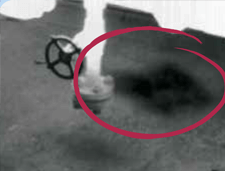

GF320: Hydrocarbons

Optical gas imaging cameras like the FLIR GF320 help to spot leaks in piping, flanges and connections in petrochemical operations. The GF320 can rapidly scan large areas and pinpoint leaks and is ideal for monitoring plants that are difficult to reach with contact measurement tools. Literally thousands of components can be scanned per shift without the need to interrupt the process. It reduces repair downtime and provides verification of the process. Above all it is exceptionally safe, allowing potentially dangerous leaks (e.g. methane) to be monitored from several meters away.

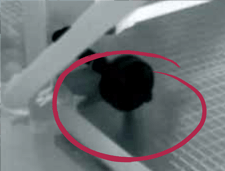

GF346: Improving workplace safety

Optical gas imaging cameras are an efficient way to inspect the workplace for dangerous gas leaks. This can especially be useful in foundries or in other processes where significant amounts of carbon monoxide (CO) are generated. CO is a colorless, odorless gas usually formed during the combustion process. Anywhere there is a heated process leading to the formation of smoke such as moulds and cupola furnaces CO will be present. Workers on charging platforms or catwalks can unknowingly breathe high concentrations of this gas. This can block oxygen being transported, from the lungs, causing the worker to suddenly lose consciousness. High concentrations may prove rapidly fatal without any warning symptoms.

GF309: Furnace inspections

The FLIR GF309 is designed for high temperature industrial furnace applications. These cameras are ideal for monitoring all types of furnaces, heaters and boilers, particularly in the chemical and petrochemical industries. Custom-built to see through flames, the FLIR GF309 also features a detachable heat shield designed to reflect heat away from the camera and camera operator, providing increased protection.

GF343: Leak tightness testing

Carbon dioxide (CO2) is considered to be a relatively inexpensive tracer gas for tightness testing. The method is also reliable, can be used to test complex equipment, and CO2 is easy to obtain. With optical gas imaging cameras, like the FLIR GF343, you can see CO2 leaks quickly, easily, and from a safe distance. This is very helpful at turnarounds and shut-downs to test the inertization and filling of the equipment.

GF306: Crackers , ammonia, SF6

Cracking is a conversion process used in petroleum refineries which converts the high-boiling, high-molecular weight hydrocarbon fractions of petroleum crude oils to more valuable gasoline olefinic gases and other products. Gases escaping from the cracking process can be highly flammable and dangerous. Being a non-contact measurement device, OGI cameras like the FLIR GF306 are ideal for monitoring chemical plant process areas/operations, such as steam crackers and reformers, especially for components that are difficult to reach with contact measurement tools.

High Sensitivity Mode

FLIR gas imaging cameras are surprisingly sensitive, so they can be used to detect even smaller gas leaks from about several meters away. This is especially the case when operation in the High Sensitivity Mode (HSM). This is a special feature included in all GF-Series optical gas imaging cameras. It is an image subtraction video processing technique that effectively enhances the thermal sensitivity of the camera. The HSM feature subtracts a percentage of individual pixel signals from frames in the video stream from the subsequent frames, thus enhancing the differences between frames, which make leaks stand out more clearly in the resulting images.