Thermally-Enabled Smart Solution Simplifies Tank Gauging and Leak Detection

FLIR and CleanConnect.ai Enable Remote Tank Level Monitoring and Gas Detection in Colorado

The United States is the top oil and gas producing country in the world, and the state of Colorado is a notable producer in the U.S. market. New Colorado regulations have mandated a higher level of emissions monitoring and environment protection. Colorado oil and gas producers are turning to FLIR and CleanConnect.ai for a smart solution that leverages thermal imaging and artificial intelligence for remote tank level monitoring for 24/7 gas detection.

CONTINUE READING BELOW OR DOWNLOAD THE PDF

In the United States, there are more than 900,000 active oil and gas wells. CleanConnect.ai believes that within three years, approximately 10,000 of these sites in the U.S. and Canada will be remotely monitored and managed by harnessing the power of artificial intelligence (AI) to achieve autonomous environmental compliance, field operations, and predictive optimization. With new environmental regulations passing, oil and gas producers in states like Colorado are seeking solutions that enable remote tank level monitoring and optical gas imaging (OGI) for emissions mitigation. Companies like FLIR Systems and CleanConnect.ai are on the forefront of this technological push, providing tank gauging and OGI solutions to enhance operational efficiency, satisfy regulatory compliance, and support energy independence.

APPLICATIONS TO NEW REGULATIONS

Tank level monitoring is an essential practice at oil and gas well pads. Gauging tank levels allows maintenance teams to ensure there is no overflow or know when the tank is empty. Depending upon the application, gauging can also help to calculate tank flow rates and identify possible interfaces between materials that may cause buildup (sludge) or emulsions.

Traditionally, operators have used guided wave radar for tank maintenance, which involves opening the “thief hatch” at the top of the tank. Opening the thief hatch is a large emitter of volatile organic compounds (VOC), which damage the environment and raise safety concerns for workers. In the state of Colorado, Senate Bill 19-181 (SB 19-181) strictly prohibits the opening of thief hatches for these reasons, with specific controls of hydrocarbons via oil and gas emissions outlined in Colorado Regulation 7. All of which, make non-invasive and remotely operated solutions for tank level monitoring a necessity.

Another facet of the Colorado SB 19-181 regulation is the requirement of real-time gas emissions monitoring. Currently, many sites employ leak detection and repair (LDAR) teams to inspect for leaks and record results every 30 days. But this solution can be labor intensive, as there are often hundreds, if not thousands of components to inspect across numerous locations.

Even if operators were to hire ten times more LDAR teams, it would still be nearly impossible for the teams to provide continuous gas emissions monitoring for the 43,000 pads in Colorado alone. This makes finding an autonomous solution crucial to comply to industry regulations, reduce operating costs, and increase pad site efficiency.

PUTTING TOGETHER AN INNOVATIVE SOLUTION

In the wake of emerging environmental laws in the oil and gas market, CleanConnect.ai began developing a solution that would leverage AI and thermal imaging to help oil and gas operators reach compliance. When looking for a thermal imaging provider, the team reached out to market leader FLIR Systems in January 2020 to collaborate on an innovative solution.

“FLIR has been great from the beginning,” said COO and Co-Founder of CleanConnect.ai, David Conley. “FLIR has years of OGI experience in the oil and gas market and understood our vision. FLIR was already up to speed on the latest regulations and was eager to see the project succeed.”

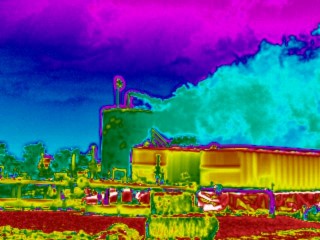

OGI cameras provide detection from a safe distance, displaying gas leaks as visible clouds of smoke. This can be shown in color or black and white as shown above.

For more than a decade, FLIR has developed industry leading infrared gas detection cameras that visualize gas leaks of various kinds. A proven solution of fixed and pan-tilt-zoom (PTZ) thermal imagers allow maintenance teams to gauge tank levels, identify possible gas leaks, and monitor assets. FLIR thermal cameras provide superior image quality, yielding video optimized for analytics that can also meet the demanding requirements for leak detection.

“Since FLIR introduced optical gas imaging in 2005 with our FLIR GasFindIR camera, we have worked with industry leaders globally to ensure operators have the right gas detection technology solutions for their needs,” said Craig O’Neill, Global Director for FLIR’s solutions in the oil and gas industry. “This new collaboration with CleanConnect.ai is a great way we can help empower oil and gas leaders to save money and better the environment by keeping gas in the system.”

Based in Berthoud, Colorado, CleanConnect.ai was founded for the purpose of protecting the oil and gas industry while contributing to a cleaner environment. By providing high-performing AI software, CleanConnect.ai’s technology helps oil and gas producers increase profitability and regulatory compliance of pad sites without having to hire additional staff.

EARLY ADOPTERS FOR SMART SOLUTIONS

If oil and gas producers fail to meet Colorado’s SB 19-181 standards, they can be subject to large fines, operational closures, environmental hazards, and injury to workers. When CleanConnect.ai approached its customers with the integrated FLIR and CleanConnect.ai solution, they were eager to implement it. In the summer of 2020, CleanConnect.ai installed the trail-blazing technology at three sites, with installation only requiring a couple of days at each pad. Each site ranges in size from one to five acres and utilizes the FLIR and CleanConnect.ai solution to monitor assets including, production equipment tanks, compressors, gas lift buildings, equivalent circulating densities, and flares.

“The entire CleanConnect.ai system is built on a platform that can create, manage, and deploy data from any IIoT device giving real-time actionable data on operations,” Conley explained.

CleanConnect.ai’s customers are some of the early adopters of the smart solution, which moves them one step closer toward autonomous operation. These oil and gas producers also serve as a model for other oil and gas customers to imitate not only throughout Colorado, but also across the rest of the United States.

HOW THE SOLUTION WORKS

For optical gas imaging at these pads, the FLIR G300a camera was installed with CleanConnect.ai’s AI software. Most gases are invisible to the naked eye without specialized technology. FLIR produces a range of OGI cameras that can aid in the detection of methane, sulfur hexafluoride, and hundreds of other industrial gases quickly, accurately, and safely—without needing to shut down the system. FLIR OGI cameras allow operators to rapidly scan a broad spectrum of equipment and survey areas that can be difficult to reach with contact measurement tools alone. OGI cameras provide detection from a safe distance, displaying gas leaks as visible clouds of smoke.

The FLIR G300a cameras were placed on pan-tilt units, allowing maintenance operators to surveil the whole property with optical gas imaging technology. Every few minutes, the detection system scans the entire pad, monitoring for abnormalities. The software from CleanConnect.ai ingests the raw data from the cameras and runs it through machine learning algorithms to identify VOC leaks. As the solution is connected directly to the user’s supervisory control and data acquisition (SCADA) system, it provides operators with information on the leak location, and severity within ten minutes of the identification of a leak.

The FLIR G300a cameras were placed on pan-tilt units, allowing maintenance operators to surveil the whole property with optical gas imaging technology.

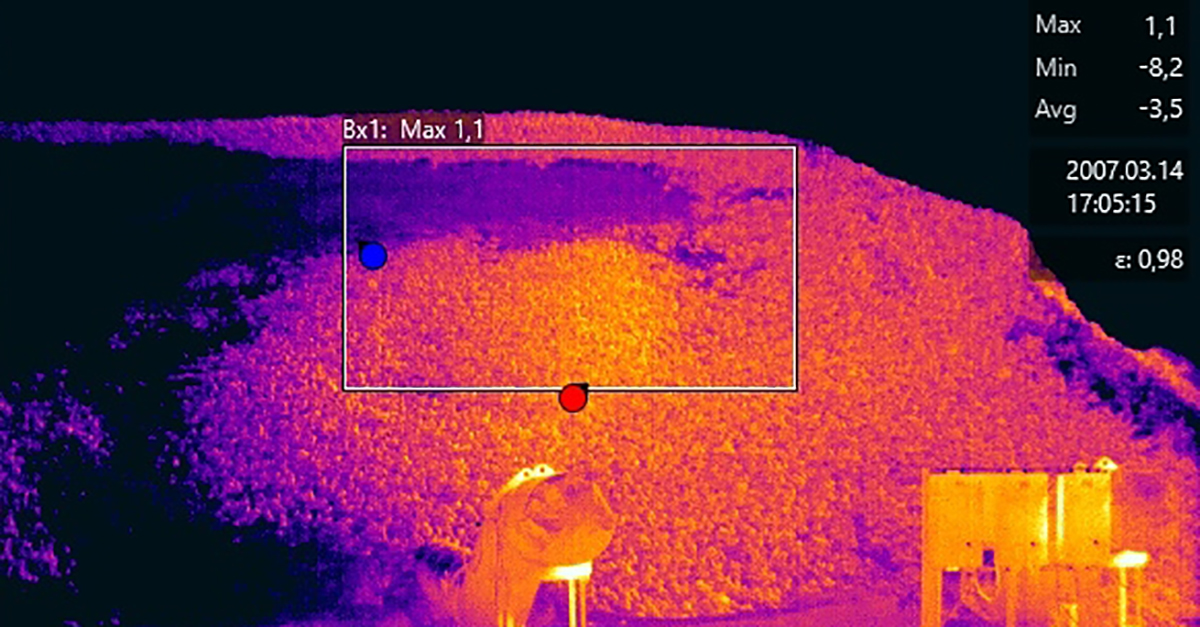

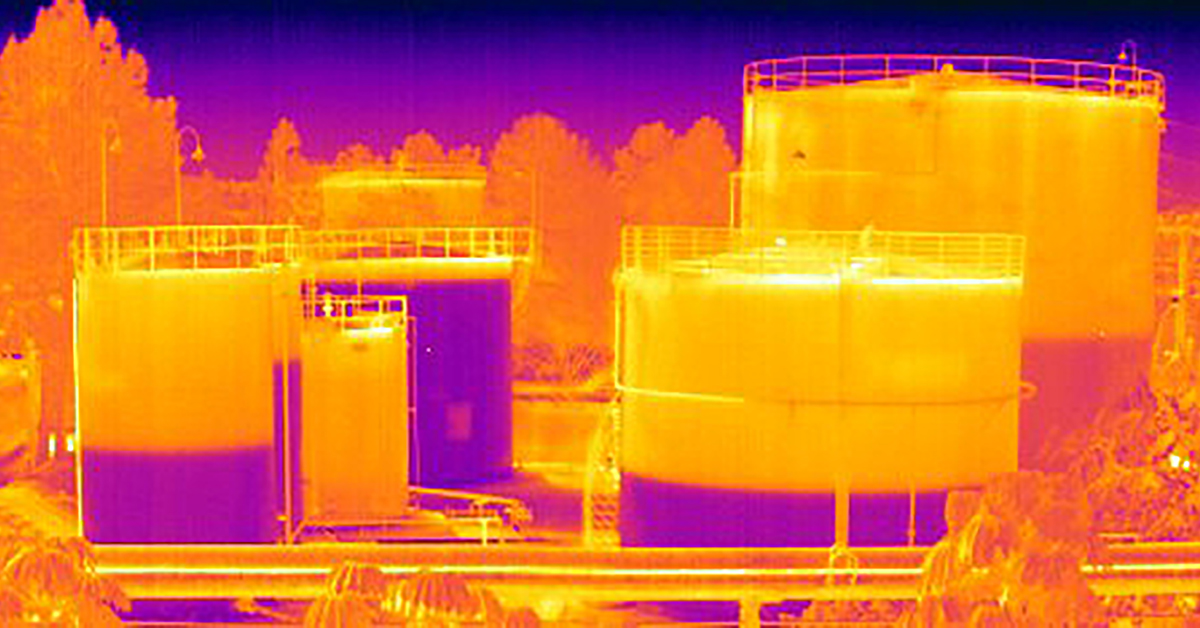

For tank level monitoring, the FLIR Elara™ FB-Series 0 was deployed on the pads to provide raw thermal imaging, which was then analyzed by the CleanConnect.ai software. The combined FLIR and CleanConnect.ai solution can gauge tank levels by observing heat changes between the exterior walls of the tank and produces a “% FULL” read out display over each tank. The tank level telemetry data is then sent directly to the SCADA system, ensuring timely data-driven alerts for operators.

RESULTS

“The FLIR and CleanConnect.ai solution saves operators millions of dollars in potential fines, and eliminates the false positives associated with competing solutions,” said Conley. “With the ability to provide continuous VOC emissions monitoring, operators see benefits across a number of indicators, preventing environmental damage and changing the public perception of the industry.”

These autonomous solutions require less staff, reducing the overall operator footprint and ultimately lowering operating costs. The system is also designed to fully meet EPA Method 21 AWP and Quad Oa (EPA 40 CFR Part 60, Subpart OOOOa) specifications, the current industry standard used by LDAR teams.

Opening the thief hatch is a large emitter of volatile organic compounds (VOC), which damage the environment and raise safety concerns for workers.

For tank level monitoring, the FLIR and CleanConnect.ai solution have been shown to be as accurate as guided wave radar, without ever requiring operators to open a thief hatch; this eliminates thousands of metric tons of VOC gas emissions. The autonomous nature of the FLIR and CleanConnect.ai system increases worksite safety and wellbeing for employees. It also eliminates high-risk practices through remote monitoring, which ensures that maintenance teams no longer physically expose themselves to harmful gases. The result is greater efficiency, public safety, environmental health, and peace of mind.

More information about optical gas imaging cameras or this sample application can be found here.